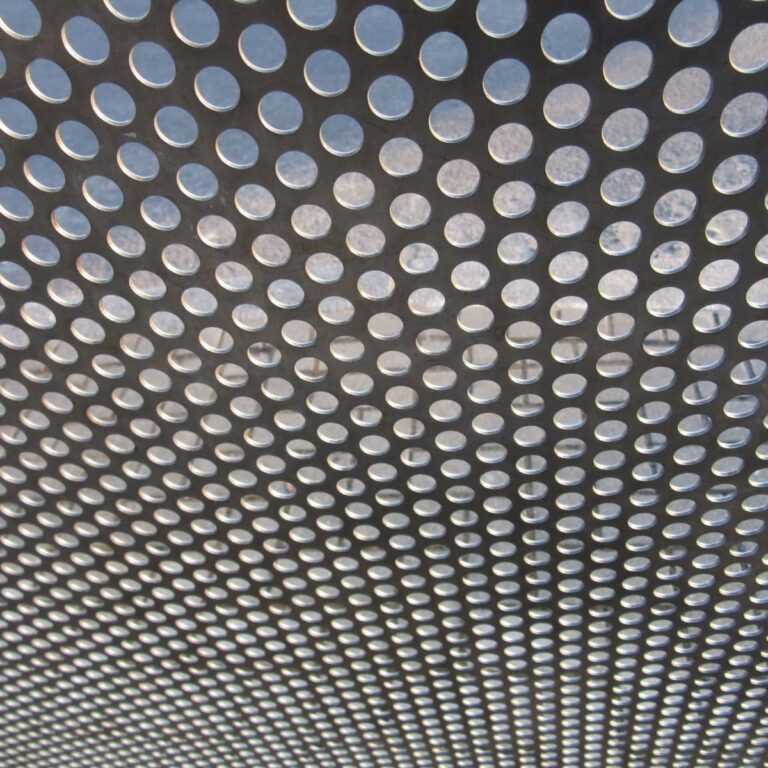

Perforated Stainless Steel

What is

Perforated Stainless Steel?

Perforated stainless steel is a type of sheet metal defined by the presence of a pattern of holes. A machine punches or stamps the metal sheet to obtain the desired hole pattern. This is also referred to as perforated plates, perforated sheets, or perforated screens. Stainless steel, cold-rolled steel, and aluminum are the most common types of metals used in perforating.

First developed 150 years ago, perforated steel sheets were used in the mining industry as a means to filter coal. At that time, the means of perforation were through laborers manually punching the patterns of individual holes into the steel sheet. Nowadays the process is much more efficient as a machine simultaneously punches any number of patterns onto the steel sheet through an array of punching needles.

How Perforated Stainless Steel

Sheets are Made

In the process of manufacturing perforated metals, a sheet that is thin and flat is utilized. This allows for the stainless steel to be cut and bent into the desired shape. The thickness of the sheet is specified in gauges; the larger the gauge number, the thinner the metal.

When perforating stainless steel, the commonly used method involves the use of a rotary pinned perforation roller. With this method, a large cylinder covered with a pattern of sharp, pointed needles punch holes into the sheet. As the stainless steel sheet is run across the perforation roller, it continuously revolves to create a uniform perforation pattern on the passing steel. In addition to producing a variety of hole sizes, the needles can also be heated to melt the stainless steel as it is perforated to form a reinforced ring around the perforation.

The “die and punch” method is also a common means of perforating. In this process, a sheet of metal filled with needles compresses on and punches holes in the passing stainless steel. The remaining pieces of steel left by the punching are then sheared off and the surface is smoothed out for a nice, clean finish. This die and punch method is efficient and is used to perforated large surfaces of sheet metal at a high rate of speed.

Needing perforated metals for your manufacturing run? Branko Perforating handles perforating projects of all different sizes and for many different industries! We are proud to accomplish any task and job set before us! Contact us today for a quote for your perforating project with us!