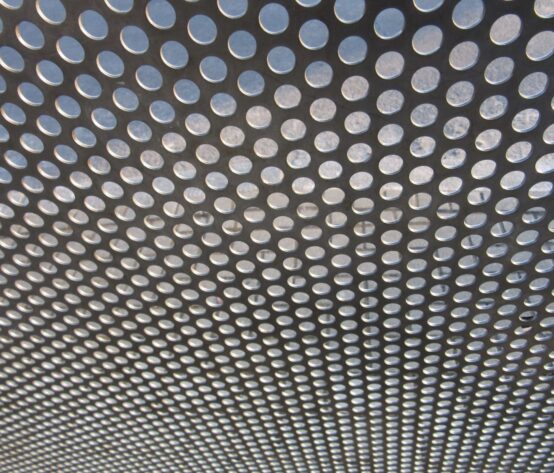

Perforated Metal Sheet

What is

Perforated Metal Sheet?

Perforated metal sheet is a type of sheet metal that has been stamped or punched with a machine to create a pattern of holes. It is also known as perforated plate, perforated sheet, or perforated screen and is most commonly made from stainless steel, cold-rolled steel, or aluminum.

Perforated metal sheet was first developed about 150 years ago as a means of filtering coal for the mining industry. However, the perforation process was far from efficient. Laborers would manually punch individual holes into a metal sheet! Over the decades since its inception, the process has improved dramatically through the use of machinery that utilizes various punching needles arranged in a number of different patterns.

How Perforated

Metal Sheet is Made

The manufacturing process for perforated metal sheet begins with average sheet metal. The sheet metal is thin and flat and can therefore be cut and bent into different shapes. The thickness of the sheet metal is specified in gauges; the larger the gauge number, the thinner the metal.

The most common method to perforate metal involves the use of a rotary pinned perforation roller. This is a large cylinder with a series of sharp, pointed needles on the outside to punch holes into the metal. As the sheet metal is run across the perforation roller, it rotates, continuously punching holes in the passing sheet. The needles on the roller, which can produce a wide variety of hole sizes, are sometimes heated to simultaneously melt the metal to form a reinforced ring around the perforation.

Another common perforating method is “die and punch” perforating. During this process, a sheet with needles is pressed onto the passing metal repeatedly, which punches holes into the sheet. The pieces remaining from the punching are then sheared off and the surface is smoothed. The die and punch method is very efficient and can perforate a large surface of sheet metal very quickly.

Need perforated metal for your manufacturing run? Branko Perforating can take on any project of any size for any industry! We pride ourselves on being able to accomplish the tasks that most of our competitors are unable to do. Contact us today for a quote on your project!